Injection Moulding Process

Injection moulding is becoming more and more popular in the construction, engineering and component parts manufacturing industries, thanks to its versatility, quality finish and simple process. A host of materials can be used to create precision parts via injection moulding, including metals (this process is known as die-casting), glass, elastomers and various plastics, such as thermoplastics and polymers.

The process is by no means brand new. The first-ever injection of the moulding machine was patented by American inventor John Wesley Hyatt and his brother, Isaac in 1872.

It was based around a large hypodermic needle that forced melted plastic through a heated cylinder into a shaped mould. Early products made using the process included buttons, collar stays and hair combs. Later on, the Second World War created an unprecedented demand for mass-produced, cheap products.

The chosen material is heated and then injected into a specially shaped mould to create a component that is exactly the right shape, colour and size required for a piece of machinery, moving part or other types of equipment.

The moulds are normally made from a strong tool metal such as steel or aluminium to help it withstand the pressure of heavy use, and precision designed by engineers to fit their exact purpose.

Uses of injection moulded parts vary in size enormously, from the tiniest machine widgets to entire car body panels. Other popular uses for injection moulding include packaging, car parts, storage containers, toys, plumbing components and medical items.

It was based around a large hypodermic needle that forced melted plastic through a heated cylinder into a shaped mould. Early products made using the process included buttons, collar stays and hair combs. Later on, the Second World War created an unprecedented demand for mass-produced, cheap products.

The chosen material is heated and then injected into a specially shaped mould to create a component that is exactly the right shape, colour and size required for a piece of machinery, moving part or other types of equipment.

The moulds are normally made from a strong tool metal such as steel or aluminium to help it withstand the pressure of heavy use, and precision designed by engineers to fit their exact purpose.

Uses of injection moulded parts vary in size enormously, from the tiniest machine widgets to entire car body panels. Other popular uses for injection moulding include packaging, car parts, storage containers, toys, plumbing components and medical items.

Many thermoplastics can be recycled, and plastic products can usually be strong enough to be reused many times over, even if they cannot be fully recycled. Plastic is hygienic, making it a great option for food and drink packaging and for medical applications.

It can be coloured any shade and used at any layer of thickness. It can withstand extremes in temperatures, exposure to water and air erosion and stand up against contact with a large number of chemicals and corrosive materials.

The plastic injection moulding process is fast, with low labour costs and high output. It can be used to create extremely small and extremely complex parts and offers the ability to include inserts, such as metal screws. Leftover plastic scraps can be re-melted to use again in a different product, thereby reducing waste.

Disadvantages include higher initial set-up costs, as an injection moulding machine can cost a lot to install, set up and maintain. There are some design restrictions too, as they rely on the ability to be able to create a mould with the desired shape.

Plus, smaller runs of parts can be less cost-effective than larger ones due to running costs and labour. There also needs to be adequate space and ventilation to operate such a machine safely, and training is required to ensure its correct use and reduce the risk of injuries.

Finally, extra time will need to be factored in for the design of a bespoke mould to create the precise components that are required. This can add to the overall production budget and timeline of a project. However, these

disadvantages can all be easily planned for and mitigated against in the early planning stages.

Many thermoplastics can be recycled, and plastic products can usually be strong enough to be reused many times over, even if they cannot be fully recycled. Plastic is hygienic, making it a great option for food and drink packaging and for medical applications.

It can be coloured any shade and used at any layer of thickness. It can withstand extremes in temperatures, exposure to water and air erosion and stand up against contact with a large number of chemicals and corrosive materials.

The plastic injection moulding process is fast, with low labour costs and high output. It can be used to create extremely small and extremely complex parts and offers the ability to include inserts, such as metal screws. Leftover plastic scraps can be re-melted to use again in a different product, thereby reducing waste.

Disadvantages include higher initial set-up costs, as an injection moulding machine can cost a lot to install, set up and maintain. There are some design restrictions too, as they rely on the ability to be able to create a mould with the desired shape.

Plus, smaller runs of parts can be less cost-effective than larger ones due to running costs and labour. There also needs to be adequate space and ventilation to operate such a machine safely, and training is required to ensure its correct use and reduce the risk of injuries.

Finally, extra time will need to be factored in for the design of a bespoke mould to create the precise components that are required. This can add to the overall production budget and timeline of a project. However, these

disadvantages can all be easily planned for and mitigated against in the early planning stages.

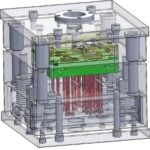

Machine used for the injection moulding process

Plastic injection moulding

Plastic injection moulding, as opposed to injection moulding using other materials such as metal or glass, has many advantages, not least the versatility of the plastic itself, which can come in almost any colour, and be moulded into any shape or size. Plastic is durable, hygienic and easy to get hold of. Many types of plastic can also be recyclable, such as thermoplastics, making them a great option for many sustainable projects too. below is the injection moulding process.Injection Moulding Process Step by step

- The whole process around plastic injection moulding begins with taking the raw plastic material in the form of granules or tiny pellets. This is then fed through a hopper and melted at high heat. When the plastic is soft enough, it is then injected under pressure into a single or multi-cavity mould to produce the desired shape or shapes. Then, the plastic parts are left to cool down enough to harden and solidify. At that stage, the injection mould is opened up and the new plastic component is released by means of moving rods, plates or an air blast, ready to be put into its intended use.

- The mould itself consists of two separate parts – the injection mould that shapes the plastic entering the machine and the ejector mould that pushes the solidified product out the machine, ready for it to continue its journey along the production cycle. The moulds must be treated with the utmost care to prolong their useful life. Ideal humidity and temperatures must be maintained to ensure optimum performance and to prevent warping.

- The process is quick and effective, enabling the production of large numbers of plastic components of the same shape and size to take place within shorter time periods, while still managing to ensure astonishing levels of accuracy and a high-quality finish. As with any manufacturing process, plastic injection moulding doesn’t come without its issues, most of which can be corrected with the right technical know-how.

- Common problems include blistering, burn marks, colour streaking, crazing and twisting, all of which affect the quality and finish of the plastic parts being produced. Thus, injection moulding machines must be routinely maintained and repaired as soon as any problems emerge, and the plastic parts closely inspected as they are being produced in order to prevent delays in the production cycle.

- Such is the versatility of plastic injection moulding that various methods can be used to generate different finishes. For example, a two-shot, or multi-shot mould combines two (or more) separate materials and incorporates them into one finished plastic part. This technique is ideal for softer finishes for items such as drawer knobs, or when a part needs to be made of more than one colour or offer different, yet complementary characteristics.

Advantages and disadvantages of Injection Moulding

Choosing whether or not to use plastic injection moulding in a manufacturing process is a decision that must be based on the individual project requirements. There are both advantages and disadvantages to the process. Plastic as a product has many advantages. It is durable, flexible and very easy to shape into the exact form that is required.

Final medical products made by injection moulding