Completing a successful injection moulding project takes skill and dedication at every step of the process. From the initial client brief to delivery of the finished product, we insist on precision, quality workmanship and a fine attention to detail. Here is some insight into how the process works.

Getting going

After the client has conformed us with their order and we agreed on a price, we will assign a project manager who will be preparing everything to make it run smoothly. Project guidelines are drawn up and studied by the entire team. Project manager keeps in close touch with his or her client at every stage of the project time frame. Deadlines are agreed and preparations begin.

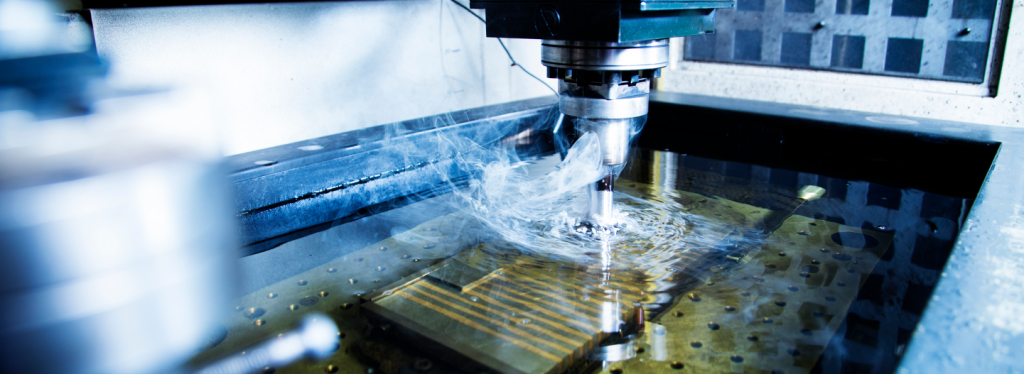

Precision engineering

Injection moulding isn’t just about pouring liquid into a mould and waiting for it to cool. Very precise temperatures are involved and the materials and equipment used are carefully inspected in a rigorous quality control process. Everything starts with the raw plastic, or resin, stored in pellet form and selected to match our client’s requirements, including colour.

Feed the machine

The pellets are fed by computer into our state-of-the-art moulding machine where they start the journey in a dedicated hopper. The hopper then moves the pellets into the machine as they are required. The plastic first moves to the injection unit, where it is rotated and heated up from the outside until it reaches the correct temperature. The computer software ensures the correct temperature and consistency is reached for the specific job underway.

Injection initiation

Once the plastic is fully melted, it gets injected via a large screw pushing forward into the barrel to force the plastic out the other end via a nozzle. The nozzle joins with a hole in the mould that will help shape the final product. The mould determines the shape of the finished, cooled plastic and can be designed to match project specifications exactly. Moulds normally comprise two separate parts that are pushed together to create the correctly shaped cavity for the melted plastic to cool and solidify.

End product

As the plastic cools and solidifies, it pushes the mould apart. As it opens, internal pins inside the mould pushes the newly formed plastic part out of the machine, ready for inspection. As the cycle ends, all the machine parts move back into place, ready to start work on the next plastic component. And so, the process starts all over again