One manufacturing technique that has become very popular with manufacturers all over the world is 2K injection moulding. Also called two-shot injection moulding, the process involves two injections, instead of one. The process is a low-cost, efficient way of producing high quantities of top-quality plastic parts that are both uniform and robust.

The 2k Injection Process

The process works via a moulding machine that has two injection nozzles attached to it instead of one. This allows two different types of plastic or raw materials to be loaded into the mould cavity simultaneously. Often, the materials combine one rigid plastic, such as polypropylene and a more elastic variation like TPE. By combining two different types of plastic, the end result can be more versatile. Components can be far stronger and consist of a more complex design than when only one plastic is used.

A rigid material tends to be injected first to create the first shot that will make up the part. The mould then rotates to a second position before the second, softer material is loaded and sent into a specific area of the first shot. It is vital that these two mould cavities do not have any cracks or areas where leakage could occur between the two injection shots, which would affect aesthetics and compromise performance. Each stage must be allowed adequate cooling time as well, to ensure that they solidify correctly and bond together properly. Finally, the mould’s design must account for extras, such as over-moulding and inserts so that these can be incorporated seamlessly into the finished components.

Effects of 2K injection moulding on finished products can include adding different colours and textures or adding to the overall functionality, for example by adding a soft element over the harder support section. This latter use enables products such as toothbrush handles that have a hard part and a smaller softer area to make it easier to grip it when brushing teeth. Materials used must be compatible with each other, with similar melting points to help them bond properly and prevent stress points or areas of weakness in the finished product.

Common Applications

Thanks to the combination of two different materials, the uses of resultant products and components can be far more varied than in other forms of plastic injection moulding. For example, shapes can be more intricate and design features more ambitious. The 2K injection moulding process is common in the medical sector, due to the complicated nature of implements, tools and devices that are involved. Some medical applications include syringe plungers with a soft, flexible tip; inhalers that need tight seals around the mouth and soft medical tubing. 2K injection moulding can also be used to make complex surgical instruments such as forceps and clamps.

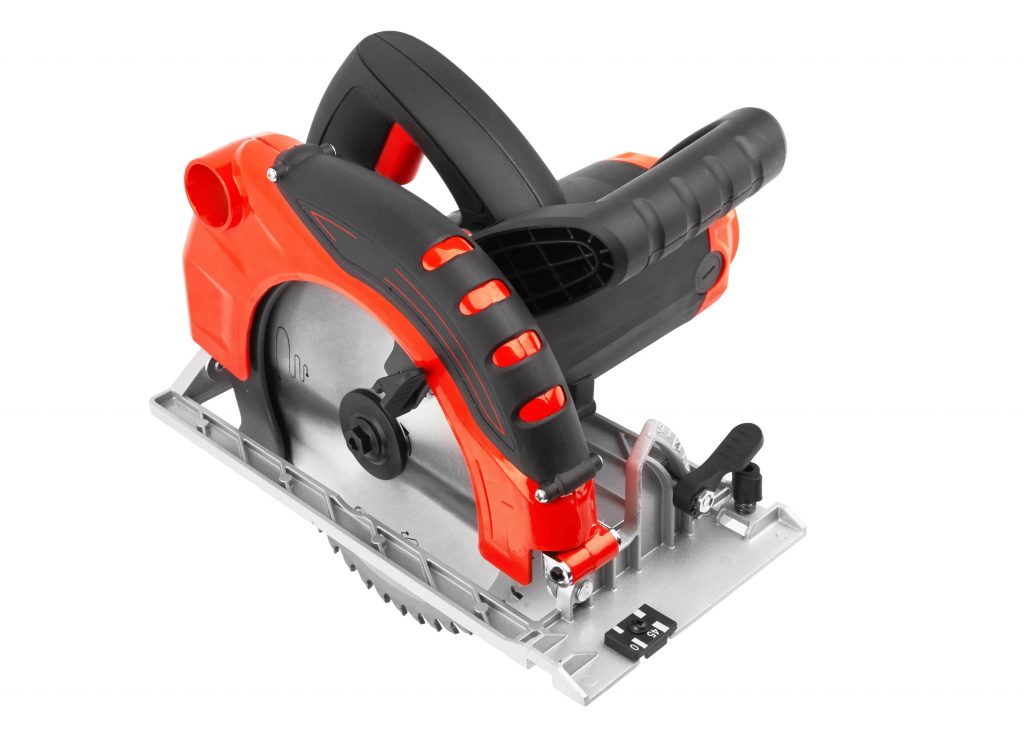

Other sectors that make use of the versatile manufacturing process include toys (e.g. building blocks, and craft or model kits that must fit together exactly), consumer electronics (keyboards, remote controls, phone casings and device buttons that must work flawlessly every time), automotive (complex gears, gaskets and interior trim that will compromise a vehicle’s overall performance if design specifications are not met), protective packaging and household appliances (soft grips for power tool handles, ergonomic utensils etc help make their use easier and more comfortable, especially over longer periods of time).

Benefits To Using 2k Injection Moulding

As well as the complexity of design and overall versatility already mentioned above, the process enables more intricate items to be made in one machine, thus reducing production and assembly times and lower overall costs. Even though initial investment costs may be higher than with other injection moulding processes, these can soon be recouped due to the ability to produce high-precision parts with extremely tight tolerances and enhanced aesthetics.

Such high precision work makes 2K injection moulding ideal for multi-component assemblies such as automotive gears and complex machinery components that rely on total adherence to the provided design and specifications to work correctly. Finally, the process reduces waste as manufacturers need only use exactly the right quantity of materials, so do not need to factor in any excess that will not be used in the end. This also helps keep costs down when ordering the materials to be used.