Award-winning plastic manufacturer for your food safety needs

Food grade plastic injection moulding is a manufacturing process in which plastic parts are created for the food industry. A popular plastic that is utilised in the food industry is High-Density Polyethylene (HDPE) – a very versatile petroleum thermoplastic. It is a common packaging choice for water bottles, among its vast range of applications.

For food production companies, plastic is a popular packaging option as it is versatile and inexpensive. The materials chosen must hold up against certain external conditions and adhere to strict laws to be considered food-grade. The team at Adreco works hard to bring you top-quality plastic products in line with FDA standards and market trends.

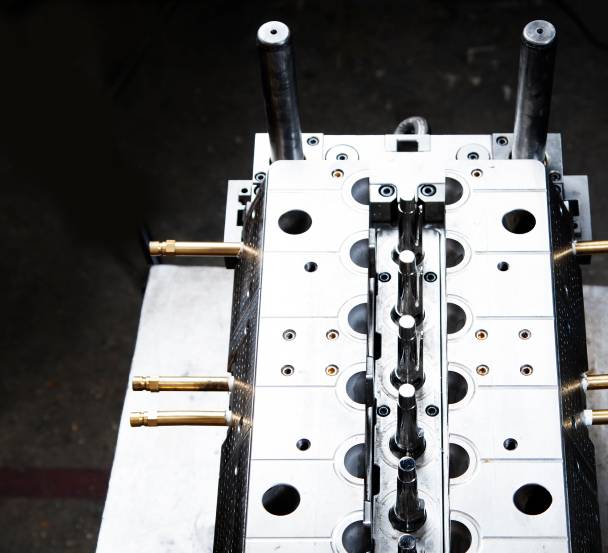

Adreco is a trusted precision injection moulding company with over 40 years of experience in the industry. We are dedicated to delivering high-quality tooling and moulding services to a range of industries. We work with both local and multifaceted businesses. As an award-winning company, our team can guarantee exemplary service and excellent value for money for our clients.

Adreco Plastics collaborates with large grocery stores and individual small food and beverage businesses to create custom plastic injection-moulded products. Whether it’s large orders for popular items or specialised, unique solutions for specific needs, Adreco ensures precision and quality in every product.

The growing importance of plastic injection moulding comes down to better design potential and the speedy production process. This makes it an invaluable option for the food industry.

The fast production cycles and the low cost per part are great for high-volume products like water bottles. Not only that, but plastic injection moulding has also replaced metal in many cases to make parts for the machinery in the production process. This allows for safer and faster production runs and the lighter weight reduces fuel consumption during transportation.

Standing out from the crowd has never been more important in the food industry. As competition roars louder each year, the more innovative food companies have to become. We provide top-quality, bespoke food packaging to help your business thrive in the current market.

Our facilities are top-tier and the plastic polymers used are customisable to suit your preference. Whether you want to use recycled plastic or reduce the amount of plastic used, we can ensure your objectives are met.

To be considered safe, plastic manufacturers must make sure that food and beverage packaging abides by UK FDA specifications.

Non-reactive materials must be used, as they come in contact with food and people. Certain conditions can affect the materials and cause an adverse reaction – eventually causing potential harm to the consumer. The plastics used must also be durable throughout their lifetime, not just in processing. The materials we use are:

The plastic chosen will depend on the project’s application, but here are some common options:

The options for plastic injection moulding are plentiful, even when limited to the food-safe kind. The most popular of the bunch is HDPE, which has a variety of uses due to its durability.

Some other options for food-grade plastics include:

We are ISO certified and a member of SEDEX (the Supplier Ethical Data Exchange). Adreco Plastics is committed to employing food-safe plastics and resins to guarantee safety, durability and longevity for your products. These standards ensure food toxins or environmental factors, such as temperature or pollutants, will not adversely affect the packaging material. As a result, this minimises the risk to consumer health.

The use of plastic products is growing as it is the most preferred material used in food and beverage products. As the population keeps expanding, the demand for food will continue to rise. In turn, food producers will choose plastic for their packaging as it’s a cheap, high-volume option.

Thermoplastics have numerous uses, which include:

Our food and beverage customers have come to rely on our ability to deliver high-quality, low-cost plastic injection moulded parts, tools and components for food industries across the UK and beyond. However, we don’t just work in this single sector. We are also a leading supplier to the medical sector, as well as defence and security, agriculture, construction, retail, packaging and lighting.

Our quality standards are exacting and everything that we produce is subjected to rigorous safety testing and quality control.

To find out how our food industry moulding services can help you and your business, or to request a quote for food industry tooling and moulding, please get in touch.

We have held ISO certification since 2006, along with other industry-recognised certifications.

AdrecoPlastics © 2022. All rights reserved