Precision Engineers in Plastic Production for Tech.

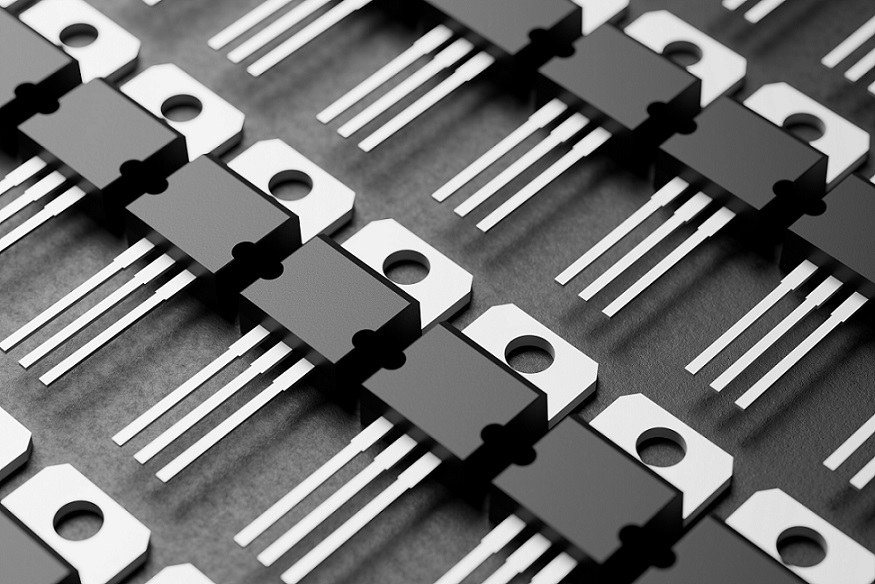

The appliance industry requires many high-quality components to create the best electronics in the market. Electronics production is complex and needs advanced designs for aesthetic and functional purposes, and thermoplastic technology is the most popular choice. The durability of these materials in high temperatures, as well as their aversion to corrosion, allows them to stand out amongst other materials.

The plastics used can be antistatic or conductive. This allows the device to maintain functionality but be lighter in weight and cheap to produce. Here at Adreco, we are committed to delivering outstanding service to our clients by providing the most competitive costs and lowest lead times

Electronics injection moulding is a crucial process for the electronics sector due to –

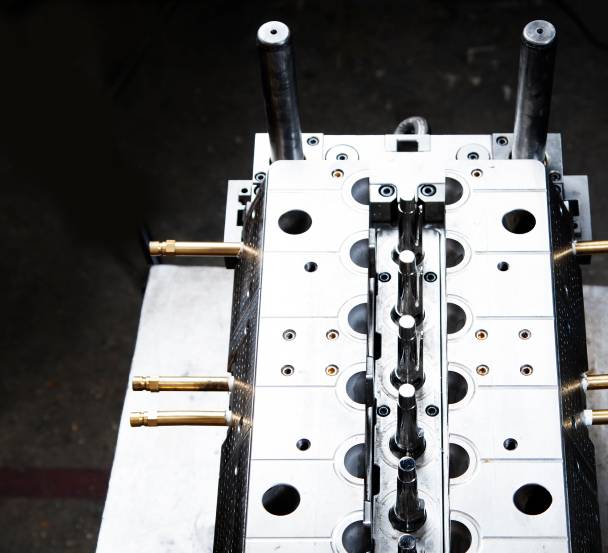

Adreco is a trusted precision injection moulding company with over 40 years of experience in the industry. We are dedicated to delivering high-quality tooling and moulding services to a range of industries. We work with both local and multifaceted businesses. As an award-winning company, our team can guarantee exemplary service and good value for money for our clients.

Adreco Plastics partners with leading electronics suppliers and small independent businesses to manufacture precise plastic injection-moulded products. Whether it’s large-scale production of popular electronic components or creating custom, one-of-a-kind solutions, Adreco ensures high-quality manufacturing to meet diverse industry needs.

A variety of electronic parts are created with plastics due to their exceptional properties, making them a suitable alternative to conventional materials. Since the plastics used can tolerate extreme temperatures and won’t corrode easily, companies see them as a practical option. Thermoplastic materials can also be mass-produced. This takes less energy, and therefore is cheaper to produce.

Plastic also enables freedom of design. Many electronics nowadays are smaller and aesthetically inclined, making plastic the best choice for lighter, sleeker devices.

Adreco works with your design and marketing team to create a unique product. We don’t just mass produce parts from a catalogue, we can also make custom moulds for individual clients.

The most commonly used plastics for electronics are ABS, polycarbonate and polyamides, such as nylon. The function of the device will be identified before deciding on the type of plastic to use in its construction. Thereafter, a suitable design plan will be proposed. Tell us your vision and we will offer our expertise on how to hone the design to create the best possible product.

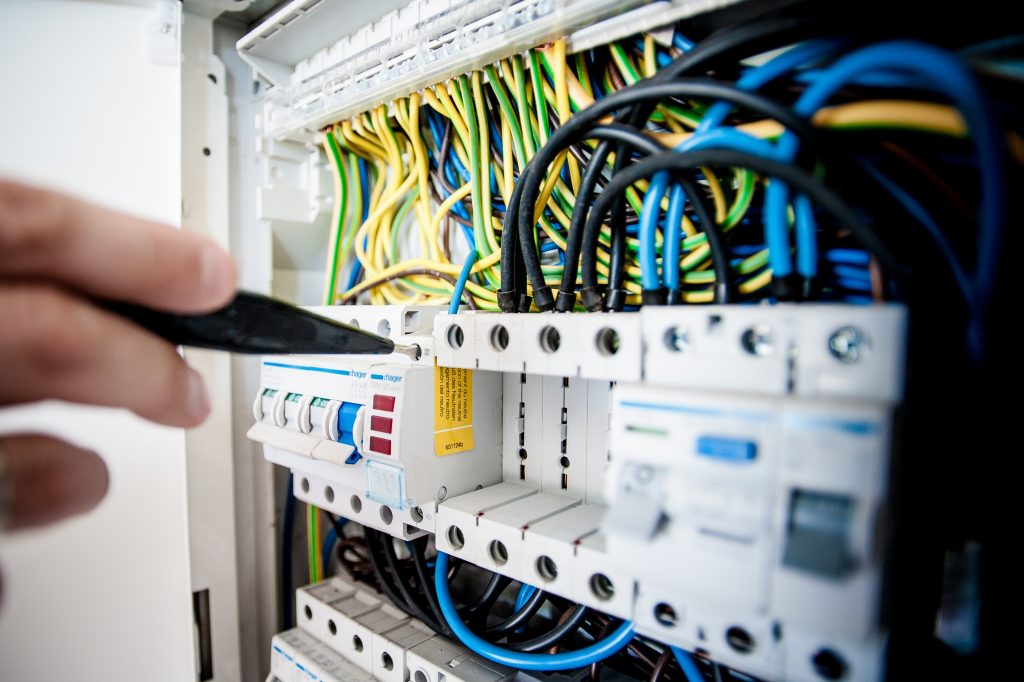

When it comes to choosing the right plastic, the purpose of the appliance must be known. If your project requires electrical wiring, then a flexible and chemical-resistant plastic will be selected for its versatile properties.

Some products require lightweight plastics – phones for example. The functionality of the appliance is protected as plastic polymers provide heat and electrical insulation. Plastic casings can keep electric currents safely contained within a device, making it run more efficiently and protecting the consumer from the risk of electric shock.

As for heat, plastics make poor conductors. Some manufacturers also make their plastics fire-resistant for additional levels of safety.

We are proud of our track record of delivering mouldings on time and to budget, working round the clock – in three shifts, five days per week if necessary – to complete your order.

A rainbow of resins offering different capabilities caters to the appliance industry. Here are some of the most popular resins and the functions they serve:

ABS (acrylonitrile-butadiene-styrene) is a type of thermoplastic with medium strength and is generally well-suited as an electronic casing material. It is not suitable for outdoor use as it is not very UV-resilient. It is used for devices like telephone handsets, keyboards and monitors.

PC (Polycarbonate) is a popular polyester plastic as it is very strong and has high heat stability. It can replace metal components and be used to make things like CDs.

PA (Polyamide aka Nylon) is a tough and lightweight polymer. On average, it offers good wear-resistance and is used to make things like adapters and food processing bearings.

TPU (Thermoplastic urethane) is a highly scratch and chemical-resistant polymer. It is usually combined with other thermoplastics to increase their tensile strength.

HDPE (Polyethylene) is the most common type of resin and is highly chemical resistant. Due to its flexibility, it can be made into cable and wire insulation.

PP (Polypropylene) is a resin that is BPA-free and has a high thermal resistance. It is commonly used for medical equipment but is also suitable for toys and kitchen appliances like kettles.

Plastics are gaining favour in the electronics industry for their technical and design-friendly features. The various uses include things like meters, sensors, phone parts, etc. The array of plastics differ in quality and so are utilised for a wide range of gadgets.

Some of the material considerations are:

We are ISO certified and a member of SEDEX (the Supplier Ethical Data Exchange). Adreco Plastics is committed to employing engineering-grade plastics and resins to guarantee safety, durability and longevity for your products. Plastics are invaluable to electronics manufacturing and have improved the efficiency and ease of use of appliances like vacuum cleaners for example!

Our standards also ensure external factors will not adversely affect the product’s performance and will keep your consumers safe and satisfied.

In every corner there is electricity, and so there must also be plastic. Plastic is used to manufacture so many household and industrial devices because it has such malleable and dependable attributes. Here are some more uses for other resins:

Our electronic customers have come to rely on our ability to deliver high-quality, low-cost plastic injection moulded parts, tools and components for electronic components across the UK and beyond. However, we don’t just work in this single sector. We are also a leading supplier to the medical sector, as well as defence and security, agriculture, construction, retail, packaging and lighting.

Our quality standards are exacting and everything that we produce is subjected to rigorous safety testing and quality control.

To find out how our electronic moulding services can help you and your business, or to request a quote for electronic tooling and moulding, please get in touch.

We have held ISO certification since 2006, along with other industry-recognised certifications.

AdrecoPlastics © 2022. All rights reserved