Minimise Downtime – Maximise Performance – Extend the Life of Your Tools

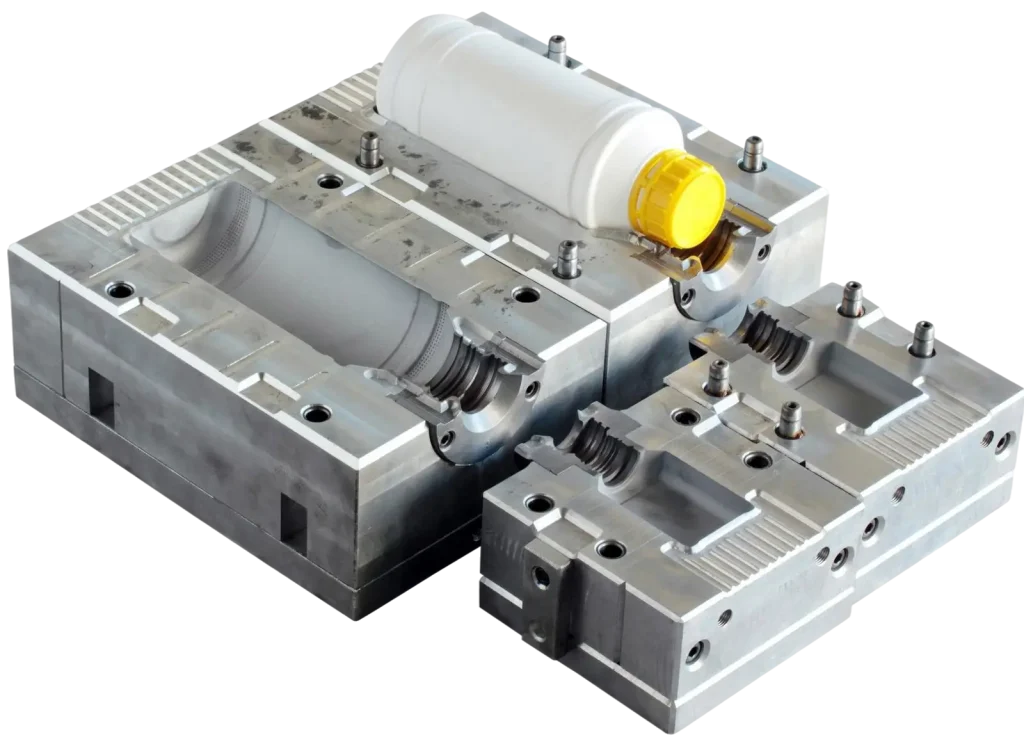

Keep Your Tools in Top Shape – Expert Repair & Servicing for Injection Moulding Tools

In the fast-paced world of manufacturing, downtime is costly — especially when it comes to critical mould tools. That’s where we come in. With decades of hands-on experience in both toolmaking and injection moulding, we offer a comprehensive repair and servicing solution that helps you get the most out of your investment.

Whether it’s a routine clean and polish, a worn core needing replacement, or full refurbishment after tool damage or long service, we’ve got the expertise and facilities to respond quickly and effectively.

We work with tools of all sizes and complexities, whether they’re built by us or by third parties. Our team understands the pressures of production environments, which is why our service is responsive, transparent, and tailored to your needs.

We have held ISO certification since 2006, along with other industry-recognised certifications.

AdrecoPlastics © 2022. All rights reserved